Why Floating Floors Fail When Laminate Flooring first hit

Why Floating Floors Fail

When Laminate Flooring first hit the United States in 1994 under the brand name Pergo, flooring installation began to change. With Laminate flooring came a floating floor with a pad underneath it. Laminate was not the first attempt of a floating floor. Vinyl manufacturers tried several times with floating sheet products. With the installation of Laminate came, under cutting of door moldings, fitting the flooring away from the wall and installing molding to hide the expansion gap.

I am still surprised today that with all the Loose Lay Flooring we have seen through the years, we still continue to have the same issues today that we first had back in 1994. People today still ignore the basic rules for a floating floor;

1. Floating floors need an expansion zone

2. Floating floors require floor prep too

3. Cabinets should not be installed on top of a floating floor

4. Do not nail moldings or transitions into the floating floor

5. Floating floors are not for every installation or everyone

In today’s flooring portfolio of products we have floating Carpet Tile, Ceramic Tile, Cork Flooring, Hardwood Flooring, Luxury Vinyl Tile, Sheet Flooring, and floating Subfloors and Underlayments. These products cover a large spectrum of the flooring market and yet they all basically have the same requirements which are listed above ….and continue to be ignored today.

Let’s look at the requirements in depth;

1. Expansion Zones – most, not all, floating floors require an expansion zone. This expansion zone is not just at the outer walls, it is around any vertical object. This includes cabinets, walls, and pipes. This expansion zone is to accommodate for the subfloor moving as it goes through seasonal change. Yes, concrete and wood subfloors will move as we go through seasonal

change. In most cases, the flooring products will not grow or change size unless influenced by an

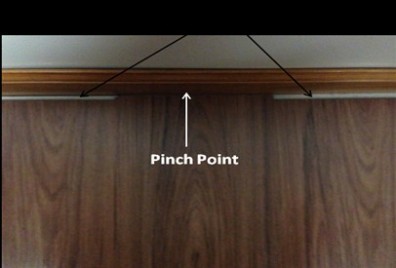

outside factor such as moisture. For example, a floating hardwood floor in a stable environment of 70°F and 35% relative humidity will have very little change, but generally requires a ½″ expansion zone. This expansion zone is to accommodate the subfloor movement through seasonal change. If one area of the expansion zone is compromised, this is an area where the flooring can hang up and create a pinch point and buckle or separate. If installing a floating LVT product that requires a ¼″ expansion zone and most of the fit pieces are at the ¼″ expansion, and one piece is tight with no expansion, this negates the expansion zone which could cause the floor to fail. It only takes one spot to cause a flooring failure. P.S. if using spacers, please remember to remove them.

2. Floating Floors Require Floor Prep – Floating floors do require subfloor prep. They are not made to hide bad subfloors. The subfloor flatness requirements for a floating floor are the same as for a glue down floor. For the flooring industry, that is ¼ inch in 10 feet or ⅛ inch in

6 feet. If the subfloor has peaks and valleys in it, you could compromise the locking system of the flooring which could cause it to disengage and unlock. With stiffer floating floors like Ceramic, Laminate and Hardwood, it could lead to creaking noises and cracking and breaking of the locking mechanism. If the floor is rough and bumpy, it will need to be smoothed or skimmed out. Going over a rough subfloor will lead to uneven wear patterns even in a

floating floor. The Clic together LVT products on the market today, require a smoother flatter floor, or they are very difficult to lock together. A customer that can’t afford floor prep can’t afford a floor either, and you can’t afford the call back!

3. Cabinets should not be installed on top of a floating floor – For some reason, people want the flooring in first, and then they want the cabinets and islands installed on top of the flooring. This cannot happen with a floating floor. You have just locked this floor down and created a massive pinch point and sometime in the near future there will have a buckle in the flooring.

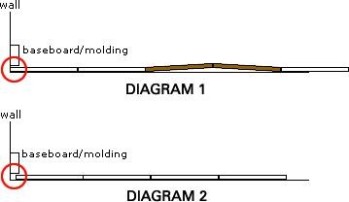

4. Do not nail moldings or transitions into the floating floor – Moldings and Transition pieces must be nailed or fastened into the wall or substrate, not into the flooring. Nailing or fastening through the floating floor creates a pinch point and will cause a buckling failure. When floating vinyl sheet floors were first introduced to the builder market the sheet flooring was installed first, then the carpet installers came in and nailed Z-Bar and tack strip into the sheet flooring which lead to the vinyl floor buckling. Unfortunately for the vinyl installer, they were blamed for the buckles and had to fix them at their time and expense.

5. Floating floors are not for every installation or everyone – Floating floors can solve a host of issues, like not having to remove asbestos flooring and floating a floor right over it. However, there are some scenarios where a floating floor is not the best option. An area that will be subject to heavy rolling loads is probably not the best option for a floating floor. A family kitchen on suspended wood subfloor that drops backs a hallway, into the laundry and powder room is probably not the best choice for a floating sheet good fiber floor. Too many pinch points. I have had calls where a floating LVT was sold for a church and they want to bolt the church pews down through the floating LVT. Like I said before, not every application is for a floating floor.

Floating floors are here to stay. Take the time to explore the entire installation scenario to ensure that this floating floor is best suited for the application you are about to sell and install it in. I also strongly suggest completely checking out the installation requirements for the flooring you are about to install. Generally the requirements are similar, but there may be some small differences from manufacturer to manufacturer.

Thanks to JJ Haines for the information!