Glue Down LVT and LVP Issues

Luxury Vinyl Tile and Plank as a category continues to grow. Along with growth come issues. Today’s article reflects what I see in the field and what I feel are some of the problems associated with glue down LVT and LVP Flooring.

Lack of acclimation – Vinyl Composition Tile is composed mostly of Limestone. Limestone has little movement when hot or cold. The composition of LVT and LVP is mostly vinyl, virgin or recycled vinyl. Vinyl expands when warm and contracts when cool. Installing LVT in new construction during the winter where they provide temporary heat can lead to issues. The LVT and LVP expands when the room is warm, and when the heat is removed, it contracts and starts to gap. Not only is the LVT and LVP affected, removing the heat also affects the adhesive. Generally, adhesives take 3-5 days to reach their cure. If it gets cold enough, the cold retards the curing process which also retards the holding power of the adhesive.

Adhesives – The adhesives used for LVT and LVP are not like Vinyl Composition Tile Adhesives. They do not have the extended working times like VCT Adhesives. Many LVT and LVP Adhesives have 1-3 hour working times compared to VCT Adhesives that have 12-24 hour working times. When you exceed the working times you are losing critical bond strength.

The adhesives for LVT are either Pressure Sensitive or Releasable. Pressure Sensitive are usually troweled on and Releasable are usually rolled. Check to see what type of adhesive you are using, how does it get applied and are you using the correct trowel notching, and what is the working time? These are big factors in having a successful installation.

When using a Releasable Adhesives with LVT products, the LVT requires an expansion zone around

all vertical objects (cabinets/pipes/walls). Using a Releasable Adhesive and fitting the LVT and LVP

tight to vertical objects is not recommended in a failure. As the subfloor contracts due to it drying out,

the LVT and LVP will start to buckle because of the pressure from the subfloor movement. Releasable

Adhesives have great shear strength and have little movement ← or →, but yet are easy to peel up

↑.When under pressure from the subfloor shrinking from drying out, the adhesive is not strong enough

to hold the LVT and LVP down.

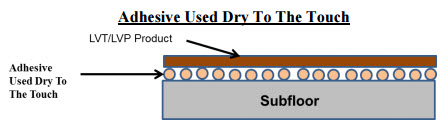

When LVT and LVP products hit the market 15 years ago, the products were mostly wet set into the adhesives. Some LVT and LVP products had to be installed using two-part epoxies because they had poor dimensional stability or the LVT and LVP was being installed over a non-porous substrate. As vinyl-backed adhesives and LVT products expanded, so did the use of adhesives being used dry to the touch. Again, respect the working time of the adhesive. Wet setting into an adhesive gives you a very strong bond. The adhesive covers the entire back of the product which gives you complete coverage. When you allow a trowel on adhesive to dry to the touch, you are only bonding to the top of the adhesive ridges (see illustration below).

When I wet set into an adhesive, I am not just troweling on the adhesive and installing into a completely sloppy wet mess of adhesive. If I were to do this, I would have adhesive coming up through the joints and the flooring product shifting around in this wet mess.

When wet setting into an adhesive, I will trowel a 2 to 3 foot band of adhesive and allow it to flash off 10-15 minutes to where I can start to see the trowel notching just starting to set up. Then I install my LVT into the adhesive and roll it. This process can only be done on a porous subfloor. If I were to do this over a non-porous subfloor like existing vinyl, I would trap all the moisture of the adhesive between the existing vinyl and the new LVT flooring. The existing vinyl will not absorb any of the moisture from the adhesive and the new LVT flooring will also not absorb any of the moisture.

Poured Gypsum Underlayments - Gypsum Underlayments continue to plague the flooring industry. When installing over a Gypsum Underlayment, it needs to be sealed with a Primer to seal up the face of the Gypsum Underlayment. Gypsum Underlayments are very porous and if not sealed properly, it will reduce the working time to half. So, my LVT Adhesive with a 2 hour working time is now down to 1 hour or less.

Product – Most of my LVT and LVP issues are with the lower cost products and when used with a lower cost adhesive. Lower end products generally are not structured like higher end products. They usually do not have a fiberglass inner layer for added dimensional stability. Again, their composition is mostly vinyl. The lower cost adhesive generally can have more filler in it than a higher end adhesive which can reduce its strength.